Understanding the Binder Joiner Test 2025: A Comprehensive Guide

As the production market develops, the requirement for standardized screening has ended up being vital to ensure quality and Akku Werkzeuge Für Heimwerker Werkzeug Set 18v Bürstenlos 5-Teilig Im Koffer (git.qiniu1314.com) efficiency. The Binder Joiner Test 2025, set to roll out in the near future, Abricht und Dickenhobel mit Spiralmesserwelle preisvergleich promises to improve making procedures and enhance product consistency throughout numerous sectors. This post intends to supply you with a thorough understanding of the Binder Joiner Test 2025, its significance, method, and crucial takeaways.

What is the Binder Joiner Test?

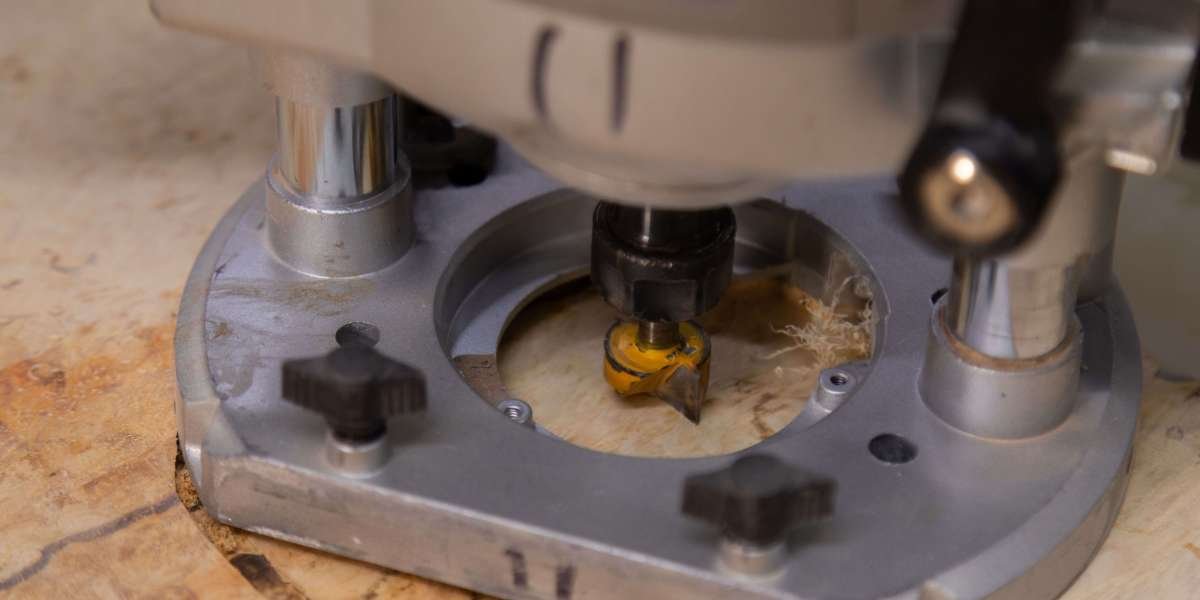

The Binder Joiner Test (BJT) is a standardized treatment designed to assess the quality and integrity of binding products used in joining parts, particularly in the woodworking and building markets. The upcoming 2025 iteration introduces modernized screening techniques that reflect the most current advancements in product science and engineering.

Value of the Binder Joiner Test

The Binder Joiner Test is essential for a number of factors:

- Quality Assurance: It ensures that bonding products can hold up against the stresses and loads expected in real-world applications.

- Standardization: The test creates an uniform standard for makers, boosting item competitiveness.

- Safety: Properly evaluated and validated joints avoid structural failures, thus guaranteeing security for end-users.

- Sustainability: The test motivates using eco-friendly binding materials by examining their effectiveness.

Binder Joiner Test 2025: The Expanded Framework

The BJT 2025 presents noteworthy changes to its predecessor, concentrating on three core areas: products, testing treatments, and evaluation requirements. The following table summarizes the upgraded framework.

| Element | Previous Test (2020 ) | BJT 2025 |

|---|---|---|

| Materials | Restricted alternatives | Large range with environmentally friendly options |

| Evaluating Procedures | Manual evaluations | Automated and digital techniques |

| Assessment Criteria | Basic performance | Thorough performance metrics, consisting of longevity and environmental impact |

Methodology of the Binder Joiner Test 2025

The Binder Joiner Test uses a rigorous method to assess binding products in a structured manner. Here's an introduction:

Step 1: Sample Preparation

- Choice of Materials: Choose suitable binding agents and substrate products that are representative of the last products.

- Conditioning: Samples must be conditioned to standardized temperature level and humidity levels to guarantee constant testing conditions.

Step 2: Joining Process

- Application of Binder: Apply the binder according to maker guidelines.

- Curing: Allow the adhesive to treat totally based upon the defined time requirements, which might differ depending upon the binder type.

Step 3: Testing Procedures

- Shear Strength Testing: Measure the shear strength of the bonded material using hydraulic presses that use steady pressure till failure happens.

- Sturdiness Assessment: Conduct cyclic loading tests that mimic real-life conditions over extended periods.

- Impact Resistance: Assess how well the bond can hold up against abrupt impacts or stress shocks.

Step 4: Evaluation and Reporting

- Data Collection: Test outcomes are tape-recorded digitally for Akku Werkzeug Set 18v Bürstenlos 5-Teilig Im Koffer (git.churiland.Com) precision.

- Performance Metrics Analysis: Compare outcomes versus the predetermined benchmarks to assess efficiency.

- Reporting: Produce a thorough report detailing findings, efficiency rankings, and compliance with market requirements.

Secret Features of the Binder Joiner Test 2025

The BJT 2025 has a number of essential functions developed to improve the total screening experience and outcomes:

- Integration of AI: The inclusion of Artificial Intelligence for predictive analysis based on screening data.

- Digital Reporting: Automated reporting systems that enable quicker analysis of information.

- Comprehensive Database: A central database of outcomes that industry specialists can access to compare materials.

Regularly Asked Questions (FAQ)

1. Who must abide by the Binder Joiner Test 2025?

Producers that produce bonded products, especially in woodworking, building, and associated sectors, must comply with the Binder Joiner Test 2025.

2. What are the primary products tested?

The BJT 2025 tests a variety of binding agents including however not limited to, PVA (Polyvinyl Acetate), epoxy resins, and polyurethane adhesives.

3. How often should products be evaluated?

It is recommended that items go through screening every production cycle, particularly when there is a change in materials or production procedures.

4. What repercussions come from failing the test?

Failure to meet the BJT 2025 requirements can lead to item recalls, loss of market track record, and prospective legal ramifications if safety requirements are not kept.

5. Can companies affect the screening criteria?

Industry feedback is motivated, and business can suggest enhancements to the testing criteria through authorities channels taken part in maintaining the requirements.

The upcoming implementation of the Binder Joiner Test 2025 represents an appealing transition toward more extensive testing standards in the bonding products market. Comprehending its framework, significance, and method can equip manufacturers and stakeholders with the understanding needed to adapt to these changes efficiently. As the market tailors up for this improvement, staying notified will be vital for success in a significantly competitive market.

The adoption and compliance with the Binder Joiner Test 2025 might well change item manufacturing, contributing not just to improved safety and quality but likewise to sustainable practices that benefit future generations.